Product Introduction

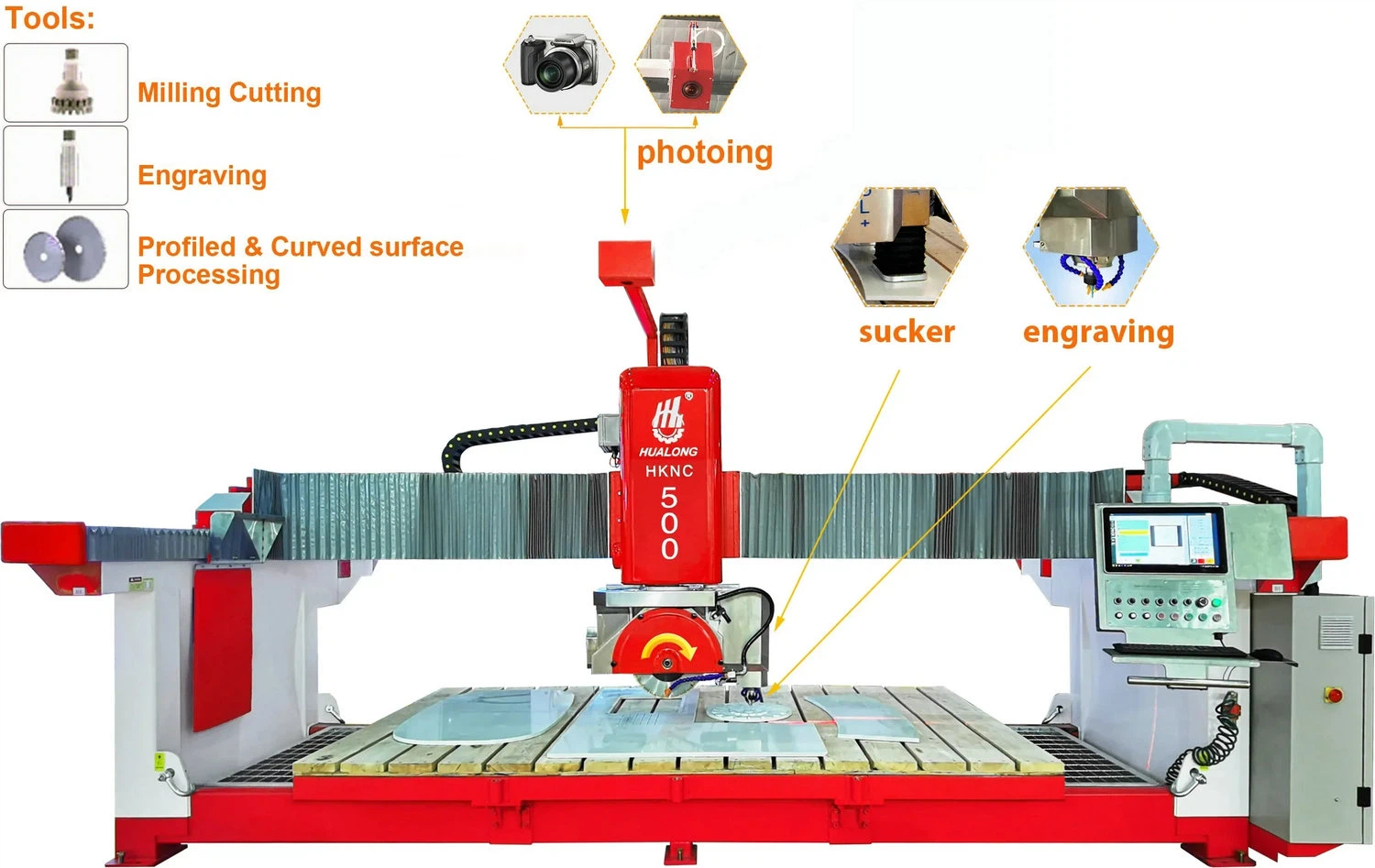

5 axis Mono-block CNC Stone Cutting Machine HKNC-500

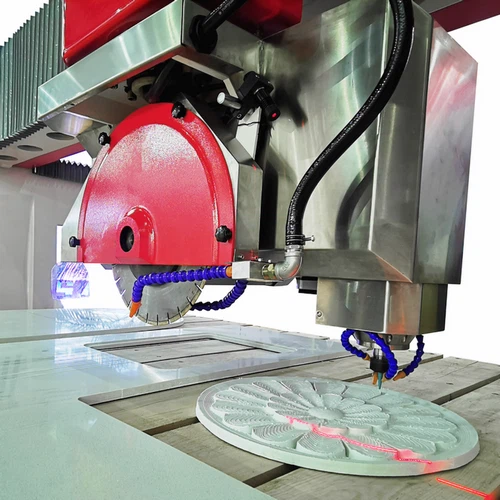

HKNC-500+ with 5 axis interpolation controlled, is a multifunctional CNC stone cutting, shaping and engraving machine built with the needs of workshops in mind, combining simplicity with maximum versatility for a minimum investment budget. It is popularly used for cutting slabs and blocks of both natural and synthetic stone, and ceramic.

Functions:

* make vertical, inclined& horizontal Cut with Disc Blade

* cut curves with Contour Cutting

* machine with the Core Tool such as drill, end mill & excavation wheel

* Incremental routing for sink cutting, profiling & engraving

Match these capabilities with Italian ESA CNC system, digital servo motors and CAD CAM drawing software to make all kind of cuts with ease. HKNC-500 can also been equipped with a vacuum manipulator for the automatic moving of slabs to optimise workpiece usage during the cutting process.

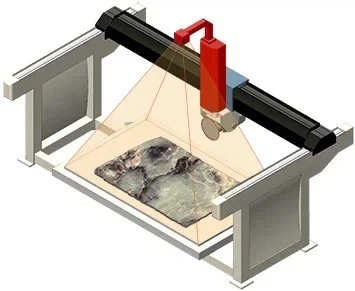

SLAB IMAGE CAPTURE:

The application allows to acquire and process the slab photo, by correcting the lens distortion and rectifying it. Through the acquired image, the shapes can be arranged on the slab avoiding material imperfections while identifying the nervures that need to be machined; it is also possible to qualify the slab edge geometrically.

DRAWING AND DESIGN:

It is possible to define the shapes being machined:with 2D CAD tools/by importing a DXF/DWG file with the automatic acquisition from a photo (using the photo-digitizer module)by importing a list from a proprietary format: Excel, CSV

The shapes begin machined will be grouped in an itemized list.

SHAPES POSITIONING:

The shapes can be arranged on the slab both with manual and automatic nesting.

The shapes being nested are loaded from the active itemized list.

MACHININGS

Once the shapes are arranged on the slab, the cutting sequence can be optimized. In this phase the overlapping cuts are removed, the colliding cuts are trimmed, the uncomplete ones are completed with a rest machining, and the cutting order is optimized to minimize the head rotations and the rapid distance traveled.

Supported machinings: linear cuts, curved cuts, inclined cuts, notch, rodding, V-Groove.

Supported cut technologies: disk, waterjet, milling and cut-drilling.

Automatic rest machining to complete the cuts using a cut-drill/mill tool or a waterjet head.

Movement and handling of the slab pieces through the suction cups manipulator to complete the cuts and to load/unload the obtained workpieces.

Material and virtual machine simulation for the immediate verification of the cutting sequence.

SOFTWARE FUNCTIONALITIES

Slab cutting handling

CAD 2D tools

Manual/automatic Nesting

Calculation of optimized trajectories for the disk cutting

Automatic rest machining to complete the cuts using a cut-drill/mill tool or a waterjet tool

Movement of the slab pieces through the suction cups manipulator

Acquisition and correction of the slab image through a camera

Solid simulation with material removal and collisions control

Features:

5 axis lnterpolation control with Italian CNC Esa system.

Italian ESA operation system and Italian Pegasus CAD CAM drawing software

Italian ESA Driver,Italian ESA Controller and ESA servo motor and Savch inverter

With office software for CAD CAM drawing at home or in office and 3D cutting(optional)

Easy to use interface with 19" color touch-screen.

Blade can rotate 0°-360° and tilt 90° for any direction's and any angle's chamfering cutting.

Working platform can tilt 85 degrees, easy for slabs loading.

Italian ESA operation system and Italian Pegasus CAD CAM drawing software

Manual cuts available for simple machining.

Nesting manual / automatic to optimize slab surface usage

Monobloc structure bridge saw will be easy for installation and loaded inside 20 foot container as a whole.

Optional - Sole engraving module with electric spindle exellent for 2D carving.

Optional - Vacumm manipulator for workpieces handling.

Optional - Photo slab for nesting and avoiding defects.

Optional - Vein match for easily matching up perfectly each vein,color at the seam of your project.

Optional - Slab thickness probe

Optional - Tool measuring system

Details Images

Control system -- CNC

Brand: ESA

Original: Italy

Top of the line CNC system with touch screen for easy setting and automatic processing. It can make a complicated machining job easy, perfect and high efficient.

Software - Pegasus CAD/CAM

Brand: Pegasus

Original: Italy

* Easy to Use -- Very user-friendly, it does not require any advanced computer skill.

* Reliable -- Frequent updates and high-quality support.

* Powerful -- Different modules and tools for plenty of technologies and machinings.

Slab Image Capture (Optional)

The application allows to acquire and process the slab photo, by correcting the lens distortion and rectifying it. Through the acquired image, the shapes can be arranged on the slab avoiding material imperfections while identifying the nervures that need to be machined; it is also possible to qualify the slab edge geometrically.

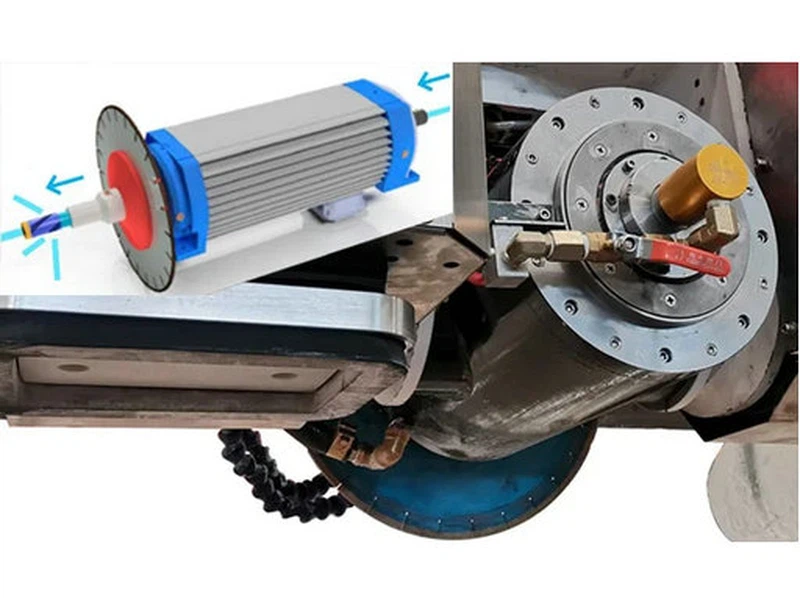

Digital Servomotor

Brand: ESA

Original: Italy

A permanent magnet brushless servomotor with intergrated drives, designed to achieve total digital integration with Esa's CNCs,creates a reliable controlling power for X, Y, Z and C axises

Electro-spindles

of high quality controlled by an inverter allowing the adjustment of the nr. of revolutions from 0 to 6000 rpm, so granting the use of blade and diamond tools such as a core drill or milling cutter. The tool change is of manual type.

Engraving Module (Optional)

* Type: electric spindle

* Rotating speed: 0-24000 rpm

* Power: 5.5 kw

Comparing with machnical spindle, the rotating speed of this electric spindle is super higher. It makes engraving fine and faster, or make curve cutting, corner cutting by milling much faster too.

Galvanization (Optional)

Galvanizing can prevent the immersion of air, water and other corrosive media to steel, improve the corrosion resistance of the machine, enhance mechanical strength, and extend the service life.

Linear Guide

Brand: Hiwin

Original: Taiwan, China

Famous products, top quality gear used on crossbeam and carling for high precision of cutting and long lifespan.

Blade Presetting Unit (optional)

Automatically measuring blade diameter and diamond tool

Slab Thickness Detector (optional)

Origin: China

System to automatically detect the thickness of the slab.

Rubber Platform (Optional)

Waterproof and no deformation

Safeguard Door (Optional)

Safe light curtain is recommended for preventing work-related injuries.

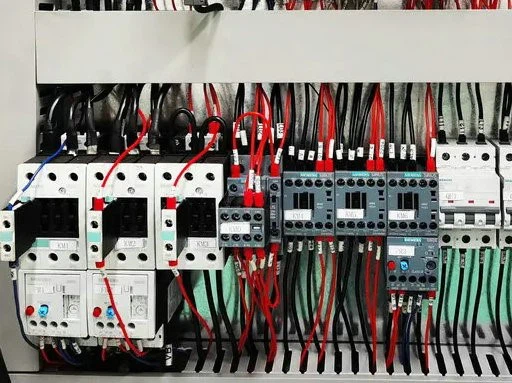

Electric Cabinet

Branded electric companets such ESA, Schneider, Sanch are adopted to ensure stable performance.

Linear Guide

Brand: Hiwin

Original: Taiwan, China

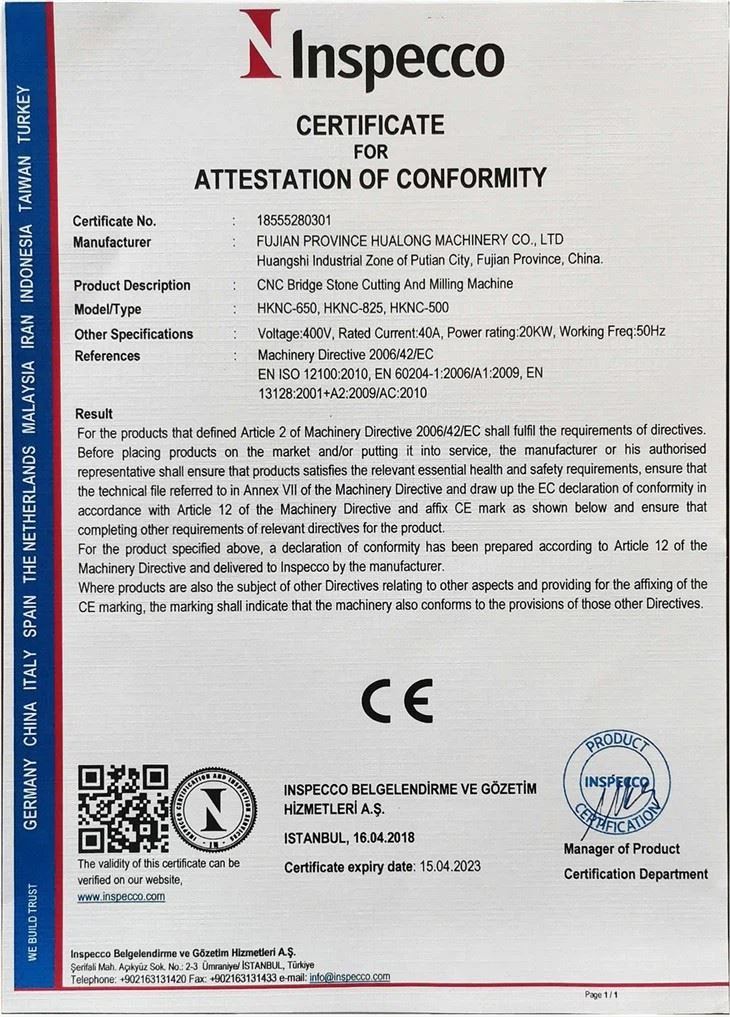

Our Certificate

slab cutting machine

CNC stone machine

water jet machine

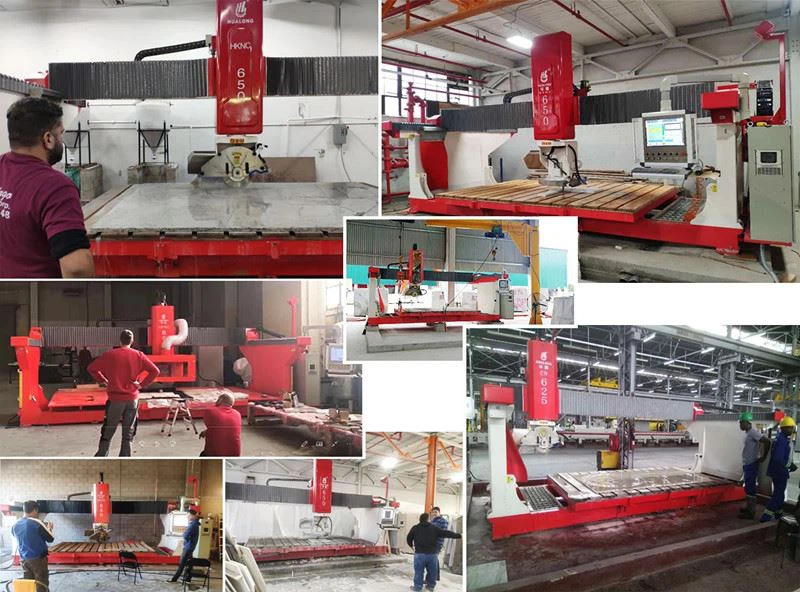

Customers' spot

Our Service

·All of our machine will be full-checked and tested by our quality control department before shipment.

·Lifetime technology maintenance in free

·Spare parts supply in free due to our defects within 12 months' warranty time and at cost out of 12 months.

·Free training for installation, operation and maintaince.

·Technical support all working days.

·English version 'instruction books', "Operation Manual" will be offered.

Packaging & Loading

1)All parts wrapped by waterproof PE film and/or air bubbles.

2)Spare and accessary parts of small size packed in plywood cartons.

3)With steel ropes to fix in container, anti-skid suitable for long distance shipment.

Workshop

FAQ

Q1: Do You Offer Free Samples?

A1: Normally we don't offer free samples. But further solutions will be discussed respectively upon request.

Q2: Can You Supply Us Wearing Parts For The Bridge Cutting Machine?

A2: Sure, it is our duty.

Q3: How About The Delivery Time After Payment For The Order?

A3: Normally 25-45 days. It depends on the ordered models, quantity and our production duty engaged already.

Q4: What Service Can You Provide?

A4: Online technology support, engineers arranged to overseas for guiding machine installation training operation, debugging and maintenance.

|

TECHNICAL DATA FOR HKNC-500 |

||

|

Diameter of saw blade |

ø400-ø500 |

mm |

|

Dimension of working platform |

3300x2000 |

mm |

|

Max. cutting length |

3300 |

mm |

|

Max. cutting thickness |

140 |

mm |

|

Max. lifting stroke |

250 |

mm |

|

Max. lifting weight by sunction cups |

200 |

kg |

|

Power of main motor |

11 |

kw |

|

Power of cutter frame reciproctating motor |

2 |

kw |

|

Power of crossbeam shifting motor |

1.1 |

kw |

|

Power of hydraulic station motor |

2.2 |

kw |

|

Power of lifting motor |

0.85 |

kw |

|

Gross power |

16 |

kw |

|

Water consumption |

2 |

m3/h |

|

Gross weight |

5400 |

kg |

|

Dimensions (L x W x H) |

5700x3260x2765 |

mm |

Hot Tags: 5 axis CNC Bridge Saw Stone Slab Cutting Machine, China, manufacturers, suppliers, factory, price, for sale, Stone Slab Saw, Automatic Granite Cutting Machine, Stone Slab Cutting Machine, Bridge Saw Manchine, Granite Slab Cutting Machine, Multi Blade Stone Block Cutter