Hi,I am Angela to serve you.Please click here to chat with me via Whatsapp +8618206025132.Tks

Hi,I am Angela to serve you.Please click here to chat with me via Whatsapp +8618206025132.Tks

Official contact:

Angela Chen

FUJIAN PROVINCE HUALONG MACHINERY CO.,LTD.

Add: Huangshi Industrial Zone, Putian city, Fujian, China 351144

Tel/Wechat/Skype: +86 18206025552

Whatsapp:+86 18206025132

Email: Angela@hualongm.com

With the rapid development of technology, 5 axis CNC bridge saw machines have become a popular choice for fabricators in the stone industry. These machines are efficient, innovative, and offer a range of benefits that make them stand out from traditional saws.

One of the main advantages of a 5 axis CNC bridge saw machine is its ability to perform complex cuts with precision accuracy. These machines can be programmed to cut intricate shapes and patterns that are impossible to achieve with manual saws. This makes them ideal for creating custom designs, such as curved edges, intricate medallions, and detailed mosaics, among others.

Another benefit of a 5 axis CNC bridge saw machine is its speed and efficiency. With advanced software and cutting-edge technology, these machines can cut much faster than traditional saws, saving time, and increasing productivity. This means that fabricators can produce more pieces in less time, which translates into increased profits.

In addition, 5 axis CNC bridge saw machines are easy to operate and require minimal training. The user-friendly interface allows operators to input their designs and start cutting within minutes. This minimizes the risk of errors and allows for a smoother workflow.

Moreover, 5 axis CNC bridge saw machines are also known for their reliability and durability. These machines are built to withstand heavy daily use, and with proper maintenance, can last for years without breaking down. This means that fabricators can rely on their machines to deliver consistent and accurate cuts day after day.

In conclusion, 5 axis CNC bridge saw machines are a game-changer for the stone fabrication industry. With their precision, speed, efficiency, ease of use, and durability, these machines offer a range of benefits that can help fabricators take their business to the next level.

This is a kind of new generation light weight stone cutting machine. Equipped with the world famous italian CNC control system and already installed CAD, CAM software. Qualified in stone processing and shaping. The machine is controlled by easy operation and interactive touch screen computer. Make your stone cutting and shaping process easy and efficient.

Main Features:

5 axes interpolated control.

Big touch screen CNC control system. Easy to control.

Photograohing camera equipped. Helps for slab positioning and typesetting. Save time and reduce the waste of processing.

Vacuum lifter equipped(optional). Easy moving slabs for cutting and processing.

Milling cutter for doing the hole drilling and sink cutting work.

Multifunctional processing function which can doing the complex work of cutting, milling, drilling and carving and even the curved surface processing.

Cutter head can tilt in 90 degrees vertical and rotate in 360 degrees horizontal. Handling chamfer cutting at any angles automatically.

Work bench can tilt in 85 degrees and all around rotate for easy slab loading and changing.

Easy for loading, unloading and installation due to the monobloc structure.

USB and WIFI connection. Easy to connect and upload your CAD/CAM files to the machine.

Parameter data

| Name | Unit | HKNC-450 |

| Diameter of saw blade | mm | 400-450 |

| Dimensions of working platform | mm | 3300*2000 |

| Max. length of horizontal cutting | mm | 3300 |

| Max. cutting thickness | mm | 90 |

| Max. lifting stroke | mm | 250 |

| Power of main motor | kw | 15 |

| Water cpmsumption | m³/h | 2 |

| Dimensions(L*W*H) | mm | 5700x3260x2765 |

| Gross weight | kg | 4000 |

Detailed Information For Spare Parts:

Control system:

Italian ESA CNC control system with touch screen for computer setting and controlling easily and visiable. Make your complicated work easily and high effficience. No need to switch from PC to machine frequently.

Digital Servomotor:

Italian ESA digital servomotor. Using a kind of permanent magnet brushless servomotor with intergrated drives, designed to achieve total digital integration with ESA CNC control system, creates a reliable controlling power for X, Y, Z, A and C axes.

Electro-spindle

High quality Electro-spindle controlled by an inverter allowing the adjustment of revolutions from 0 to 6000 rpm, so granting the use of blade and diamond tools such as a core drill or milling cutter. The tool change is of manual type.

Electric Cabinet

Using the branded electric component as ESA, Schnider, Sanch to ensure the stable performance.

Linear Guide

Hiwin linear guide used on crossbeam and carling for high precision of cutting and long lifespan.

Laser Reticule Apparatus

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

Vacuum Lifter(Optional)

Laser checking and calibration instrument to aid in lining up the cut at the beginning of processing.

|

Photo Slab System(Optional) Detecting slab with camera positioned above the machine and image acquisition software to catch the slab dimensions to be exploited in the best way possible and carry on the cutting avoiding any defects or any veins in the material. |

| Blade prosetting Unit(Optional) Automatically measuring blade diameter and diamond tool |

|

|

Slab thickness Detector(Optional) Automatically measuring blade diameter and diamond tool |

| Vein Matching Function(Optional) Easily match up each vein and seam of your project |

|

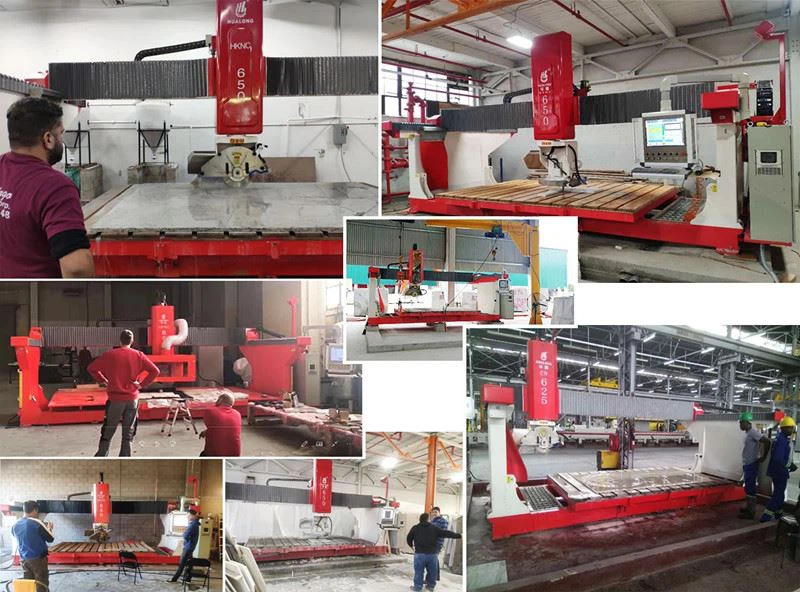

Customers' Workshop

Our factory

Packaging & Loading

Functions:

* make vertical, inclined& horizontal Cut with Disc Blade

* cut curves with Contour Cutting

* machine with the Core Tool such as drill, end mill & excavation wheel

* Incremental routing for sink cutting, profiling & engraving

Our service

Pre-sale Service

* Inquiry and consulting support.

* Technical cooperation.

* View our Factory.

After-sale Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

Q: Are you a manufacture or trader?

A:We are a leading manufacture with 30+ years.

Q:When will you ship my order ?

A: Normally 25-35 days after deposit received, If urgent, it can be negotiated.

Q: What's the warranty time?

A: One year, but the technical support will be lifetime.

Q:How can we guarantee quality?

A:We have a professional quality control team, and they will carefully check every procedure during production. And all machines will be tested and inspected before delivery.

|

TECHNICAL DATA FOR HKNC-500 |

||

|

Diameter of saw blade |

ø400-ø500 |

mm |

|

Dimension of working platform |

3300x2000 |

mm |

|

Max. cutting length |

3300 |

mm |

|

Max. cutting thickness |

140 |

mm |

|

Max. lifting stroke |

250 |

mm |

|

Max. lifting weight by sunction cups |

200 |

kg |

|

Power of main motor |

11 |

kw |

|

Power of cutter frame reciproctating motor |

2 |

kw |

|

Power of crossbeam shifting motor |

1.1 |

kw |

|

Power of hydraulic station motor |

2.2 |

kw |

|

Power of lifting motor |

0.85 |

kw |

|

Gross power |

16 |

kw |

|

Water consumption |

2 |

m3/h |

|

Gross weight |

5400 |

kg |

|

Dimensions (L x W x H) |

5700x3260x2765 |

mm |

Hot Tags: granite cnc bridge saw, China, manufacturers, suppliers, factory, price, for sale, Automatic Granite Cutting Machine, Automatic Stone Cutting Machine, Multi Blade Stone Block Cutter, Bridge Cutting Machine, Stone Slab Cutting Machine, Stone Slab Saw