Hualong machinery 2024 USA Atlanta converings

For more information, please view at:

Customer Feedbacks on Hualong stone cutting machine from the American exhibition

For more information, please view at:

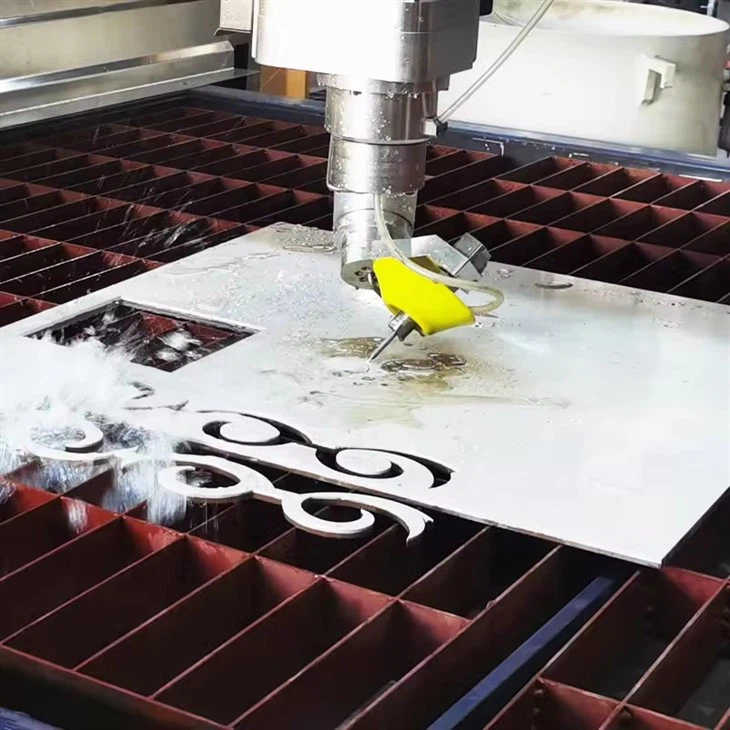

HUALONG CNC Waterjet Cutting Machine, Which Using A Very High-Pressure Jet Of Water And Abrasive (Typically Garnet) To Erode A Narrow Line In The Stock Material, Is An Industrial Tool Capable For Cutting Almost Any Material While Maintaining High Precision. This 5 Axis Waterjet Cutter Can Cut Any Angle Within +60°, It Solves The Traditional Problem Of Water Cutting Inclination, And Achieves 2D/3D Cutting Easily.The Line Cutting Accuracy Is +0.1mm, Angle Cutting Accuracy Is +0.1°. Our Machine Is Applied To Cut Bevel Surface, Straight Surface, Conical Surface, Circular Surface, Rotating Surface, Groove, Chamfer, And Arbitrary Surface.It Is Able To Cut Steel, Stainless Steel, Aluminum Titanium, Marble, Granite, Ceramic, Glass, Rubber, Foam And Many Other Materials.

model:HLRC-4020:For more information, please view at:https://youtu.be/OOJP7pO-dxY

Model:HLWJ-4020P:For more information, please view at:https://youtu.be/NZlz3lipGdI

Main advantages of CNC water jet cutter

Processable any curve cutting, flexible, convenient and versatile.

Notch is fast and smooth, no dust, no thermal deformation and no pollution. Tension-free processed parts due to minimal cutting force.

Narrow kerf – The amount of material removed by the water jet stream is typically about 0.5-1.0 mm wide. Cut width optimizes material use, increasing cost effectiveness.

Cut Recovery - Pick back up where Jet stopped.

Programmable Z axis height. Z axis retracts between pierces.

Servo motor, linear sledge and vehicles, helical rack and pinions is used for providing a rapid and smooth axial movement.

High-Performance drive system, which permit high-precision production of parts as well as the highest processing speed.

Driver system sealed against water,dust and grit. Long working life.

Technical Data For Water Jet Cutting Machine

|

TECHNICAL DATA |

|||||

|

Model No. |

HLWJ-3020 |

HLWJ-4020 |

HLWJ-2515P | HLRC-4020P | |

|

Working area |

mm |

3300*2100 |

4100*2100 |

2600*1600 | 4100*2100 |

|

X-axis stroke |

mm |

3200 |

4000 |

2500 | 4000 |

|

Y-axis stroke |

mm |

2000 |

2000 |

1500 | 2000 |

|

Z-axis stroke |

mm |

80-130 |

80-130 |

80-120 | 80-120 |

|

Max. angle of C axis rotation |

+/- 360° |

+/- 360° |

+/- 360° | 0 | |

|

Max. angle of A axis swing |

+/- 60° |

+/- 60° |

+/- 60 | 0 | |

|

Cutting accuracy |

mm |

+/- 0.1 |

+/- 0.1 |

+/- 0.1 | +/- 0.1 |

|

Repeatable accuracy |

mm |

+/- 0.05 |

+/- 0.05 |

+/- 0.05 | +/- 0.05 |

|

Traverse speed |

mm/min |

5000/15000 |

5000/15000 |

6000/15000 | 6000/15000 |

|

Main motor power |

kw |

37 |

37 |

37 | 37 |

|

Dimensions (L x W x H) |

cm |

443x278x220 |

494x280x222 |

350x220x210 | 540x283x210 |

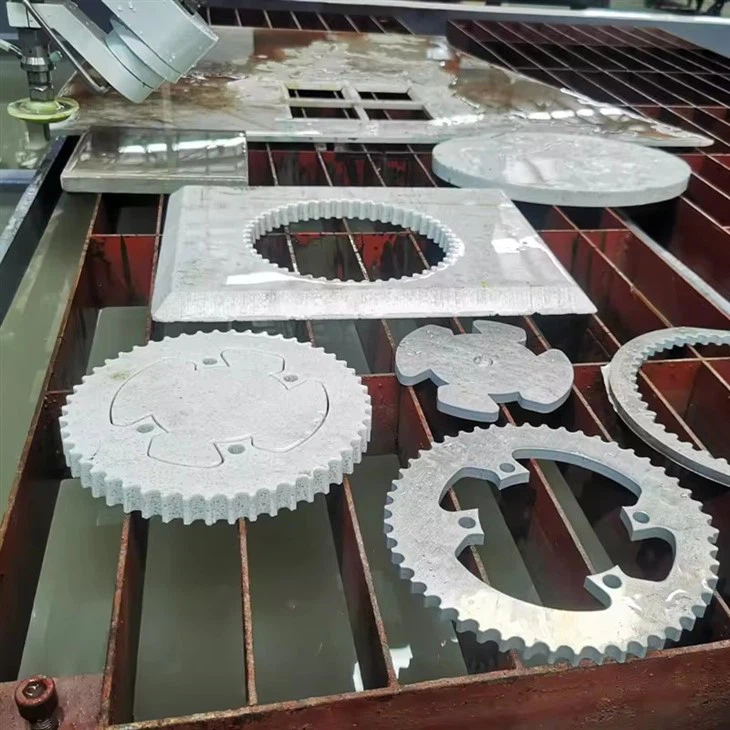

Detail Images Of CNC Water Jet Cutter

Driving System

Adopt imported core parts, durable and safe, pressurize water and continuously output water, so as to convert into supersonic water jet at cutting head.

Maximum output pressure up to 4137bar(60000psi)400MPa, Sustainable cutting pressure up to 380MPa.

Auto Abrasive Delivery System

Transfers the abrasive to the abrasive regulator.

Air valve to prevent jams and breakages

Auto control with CNC auxiliary function

Self sealing

Slightly adjust the flow.

Oil Cooled Chiller

A less mantained, more stable and better working chiller.

It cool and guarantee the hydraulic system can be used in a stable

circular manner at 42-45°C,while at 55-57°C if by water chiller.

Waterjet

software

Brand: Weihong

Original: China

A mature motion control solutions, to solve the high pressure water jet taper, towing and other technical problems, and realize perfect dynamic five-axis cutting,

Easy to operate and to learn.

Main motor

Produced by: ND

Original: China

Power: 37 kw

Efficiency: 93.9%

To generate motion energy throught electtical energy for high pressure pump

Intensifier

To produce high pressure water continuously.

Main parts come from Ashcroft, USA.

Elec-magnet

valve

.Brand: Hytek

Origin: Taiwan, China

Indicate and change advantage

Sevo moto

Brand: Weihong

Origin: China

Nr of revolutions: 0-1500 rpm

Drive X axis moving accuracy and reposefully.

Laser sensor

Brand: Weihong

Original: China

Automatic scanning precision altimeter function, ensure the knife head distance workpiece surface constant

Linera guide

* Linear sledge and vehicles, helical rack and pinions is used for providing a rapid and smooth axial movement..

* The linear slides and rails, helical rack and pinions in all systems are protected with automatic greasing pump in order to prevent rust and to continue sensibility.

Abrasive

screening

Abrasive Screening System (optional)

Last Chance Sifter Assy - Purifying waterjet abrasive, virtually eliminates abrasive feed tube and mixing tuble clogs due to foreign particles /debris entering into the main abrasive hopper when loading the cutting media.

Save time, money, material, reduce the amount of scrap/reworked parts and reduce machine downtime.

Application Of CNC Water Jet Cutter

* Stone/Ceramic industries such as used for countertops, art puzzles, flooring Inlays and mosaics.

* Glass industry, such as bathroom glass, shop window glass, automotive glass and appliance glass.

* Metal industries such as Decoration, decoration in the stainless steel and other metal cutting process, equipment cover cutting, Cutting of metal parts.

* Gasket Cutting * Foam Product Cutting.

aout us

Fujian Hualong Stone Machinery Co., Ltd. is a registered stone machinery equipment production enterprise approved by relevant national agencies. With excellent credit and superior service, Hualong has established long-term partnerships with companies at home and abroad. Located in Huangshi, Fujian Province, Hualong Stone Machinery Equipment Factory is a factory that integrates research and development, production and sales. In the production process, we strive for excellence and in sales, we always practice honesty. Hualong has a year-round ample stock, making it the preferred factory for choosing stone processing equipment. We warmly welcome friends from home and abroad to visit our factory for inspection and business negotiations.

Fujian Hualong Stone Machinery Co., Ltd. is a renowned producer of top-quality stone machinery equipment. Our company is registered and approved by the relevant national agencies. We have earned the reputation of being trustworthy and reliable, and our excellent services have earned us long-term partnerships with numerous companies both in China and abroad. Our factory is located in Huangshi, Fujian Province and is fully equipped with state-of-the-art technology for research and development, production, and sales. We are dedicated to perfection in every stage of production, and we are committed to practicing honesty in all our dealings with our customers.

Our company has a constant supply of high-quality stock for our customers. This ensures that we remain the preferred factory for choosing stone processing equipment. We have excellent facilities and a team of experts that guarantees the quality of our products. Our customers can be assured that they are receiving only the best products and services from our company.

We encourage and warmly welcome our friends both within and outside China to visit our factory. It is an opportunity to witness first-hand our commitment to excellence and honesty. We are open to business negotiations, and we assure our friends that they can expect nothing but the best from Hualong Stone Machinery Co., Ltd.

fAQ

Q: What about the leading time?

A: In general, the leading time is about 25 to 35 days. But please confirm the exact delivery time with us as different products and different quantity will have different leading time.

Q: What's the warranty time?

A: One year.

Q: If we need technical support, can you offer us?

A: Yes, we have an experienced team to offer technical support. Well-trained salespersons and engineers are always ready to respond to your technical doubts.

Q: How fast is the processing speed?

A: Speed depends on customers' materials and cutting requirement, and operator can adjust speed parameters accordingly.

Hot Tags: cnc water jet cutter, China, manufacturers, suppliers, factory, price, for sale, Granite CNC Machine, CNC Stone Working Center, Multifunction CNC Stone Machine, CNC Stone Cutting Machine, 5 Axis CNC Bridge Saw, CNC Marble Cutting Machine